Friday, October 3, 2025

Why Supplier Approval Matters More Than Ever

Discover why supplier approval is critical for supply chain resilience. Learn how to manage risks, ensure compliance, and build stronger supplier relationships.

Maikel Fontein

Oct 3, 2025

5

min

Picture a row of dominoes lined up neatly on a table. All it takes is one piece wobbling out of place for the whole sequence to collapse. That’s essentially how supply chains work. You can have airtight processes and certifications on your end, but if one of your suppliers—or even their suppliers—cuts corners, the consequences roll straight down the line to you.

This is why “supplier approval” shows up on nearly every quality questionnaire. It’s not just a bureaucratic hurdle. It’s a safeguard designed to test whether the partners you rely on are as committed to quality and compliance as you are.

And here’s the catch: auditors, regulators, and customers aren’t only concerned with your direct suppliers. They increasingly expect visibility into the entire web behind them. The quality of your suppliers’ suppliers matters just as much as your own.

The Hidden Domino Effect in Supply Chains

Supply chains are only as strong as their weakest link. If one supplier slips, the impact doesn’t stop there — it ripples outward. A single failure at the second or third tier can cause problems for every company further down the line.

We’ve seen this play out in very real ways. Consider food recalls caused by contaminated raw materials. A global brand may have rigorous quality checks in place for its own factories, but if a supplier’s supplier delivers compromised ingredients, the brand is still the one making headlines, issuing recalls, and losing consumer trust.

That’s why quality questionnaires almost always include the question: “How do you evaluate and approve your own suppliers?” It’s not just about checking up on your direct partners. It’s about demonstrating that you’ve done the work to understand where their materials, processes, and practices come from — and whether you can trust them not to topple the dominoes behind you.

What “Good” Supplier Approval Looks Like

Approving a supplier isn’t just a formality — it’s proof that you’ve done the due diligence to protect your business. Buyers, auditors, and regulators look for a few common elements in a strong supplier approval process, and the best systems bring these elements together in a way that’s both thorough and practical.

A documented approval process

A written procedure ensures consistency. Without it, approvals can become subjective — one manager might accept a supplier based on price, while another looks at quality records. Having a standard process removes guesswork.

Tip: Keep the process lean and easy to follow. If it feels like red tape, people will skip steps

Risk-based evaluations

Not all suppliers are equal. A packaging supplier may pose less risk than a raw material supplier whose inputs directly affect food safety. A risk-based approach means allocating resources where they matter most.Example: One food producer classifies suppliers into high, medium, or low risk. High-risk suppliers require site audits, while low-risk suppliers only need a certificate check.

Certification checks

Verifying certifications like ISO 9001, BRCGS, HACCP, or GMP provides external assurance. But don’t stop at collecting PDFs — make sure they’re current and relevant to the product or service supplied.Tip: Set up reminders before certifications expire. An out-of-date certificate won’t hold up in an audit.

Regular audits and reviews

Approval isn’t “set and forget.” Regular audits or performance reviews catch issues early and help maintain trust.

Example: Some companies use scorecards combining delivery times, defect rates, and complaint history to review supplier performance annually.

Corrective actions for non-compliance

Problems will happen — what matters is how suppliers respond. A robust corrective action process demonstrates accountability.

Tip: Always ask for evidence of corrective actions. A plan on paper isn’t the same as an implemented fix.

Together, these practices build confidence that your suppliers are reliable partners, not potential weak links.

5 Things to Ask Before Approving a Supplier

Can they provide up-to-date certifications — and proof they’re valid?

How do they manage traceability for their materials?

What’s their process for handling recalls or non-conformances?

How often do they train employees on quality and safety?

Do they have a process to evaluate their own suppliers?

Why Your Suppliers’ Suppliers Matter

It’s easy to stop at tier one — the suppliers you work with directly. But the real risks often sit one or two steps further back. If your supplier isn’t managing their own sourcing carefully, you inherit that risk whether you see it or not.

Second-tier risks are no longer abstract. Regulations like the European Deforestation Regulation (EUDR) require companies to prove their supply chains are free from deforestation. Human rights laws demand vigilance against child or forced labor. And food fraud — from mislabeling to adulteration — continues to make headlines worldwide.

Take palm oil as an example. Imagine your chocolate supplier is certified and audited. On paper, they look excellent. But if the palm oil in their chocolate comes from plantations linked to deforestation, then your brand carries that liability, too. In the eyes of regulators and consumers, compliance doesn’t stop with your immediate partners — it extends to every link in the chain.

This is why supplier questionnaires probe deeper than surface-level compliance. When you see questions like “Do you evaluate your own suppliers?” it’s not just bureaucracy. It’s a reminder that your credibility depends on more than your direct contracts. Customers expect transparency and accountability across the entire network.

Trust today isn’t built solely on your own performance — it’s built on the collective integrity of everyone standing behind you.

The Challenges Companies Face

Of course, knowing that supplier approval matters is one thing. Actually managing it is another. Many companies find themselves weighed down by the day-to-day reality of supplier oversight.

One major obstacle is the reliance on manual questionnaires. Information trickles in through spreadsheets, emails, and PDF attachments, leaving quality teams with data scattered across silos. Instead of enabling quick decisions, the process slows everything down.

Then there’s the problem of visibility beyond tier one. Most companies have a decent grasp of their direct suppliers, but once you go further back in the chain, information becomes patchy. It’s not unusual for businesses to have little to no insight into where their suppliers’ inputs actually come from.

Even when data does arrive, it’s often incomplete. Outdated certificates, missing documents, or vague answers create gaps that make it hard to prove compliance when an auditor or customer comes asking. Chasing down corrections can feel like a full-time job in itself.

And the compliance burden isn’t getting lighter. Regulations like CSRD (Corporate Sustainability Reporting Directive) and EUDR (European Deforestation Regulation) are raising expectations, both in terms of depth and speed of reporting. Customers and regulators want not just evidence, but evidence that’s accurate, current, and traceable across the entire chain.

In short, companies are being asked to provide sharper visibility at the very moment their processes are most fragmented. It’s no wonder that supplier approval often feels less like a control measure and more like a never-ending paper chase.

How to Strengthen Supplier Approval Without Drowning in Paperwork

The good news is that supplier approval doesn’t have to be an endless cycle of chasing emails and updating spreadsheets. With the right structure, it becomes a process that protects your business while strengthening supplier relationships.

A few practical steps can make a real difference:

Standardize supplier questionnaires

Having a single, consistent format reduces confusion and makes responses easier to compare. It also saves your suppliers from answering slightly different versions of the same question for different departments.

Use risk scoring to prioritize audits

Not every supplier needs the same level of scrutiny. By assigning risk levels based on product type, geography, or past performance, you can focus resources where they’ll have the biggest impact.

Keep supplier documentation updated in one place

Centralizing certificates, audit reports, and approvals eliminates silos and helps ensure that nothing slips through the cracks. It also makes audits much less stressful when everything is ready to hand.

Collaborate on continuous improvement

Supplier approval isn’t just about passing or failing. Working with suppliers to address issues and raise standards builds stronger, more resilient partnerships over time.

How Passionfruit Can Help You Achieve This

Even with the best intentions, many companies struggle to turn supplier approval into a smooth, repeatable process. The information exists, but it’s scattered across inboxes, spreadsheets, and filing systems. That’s where Passionfruit makes the difference.

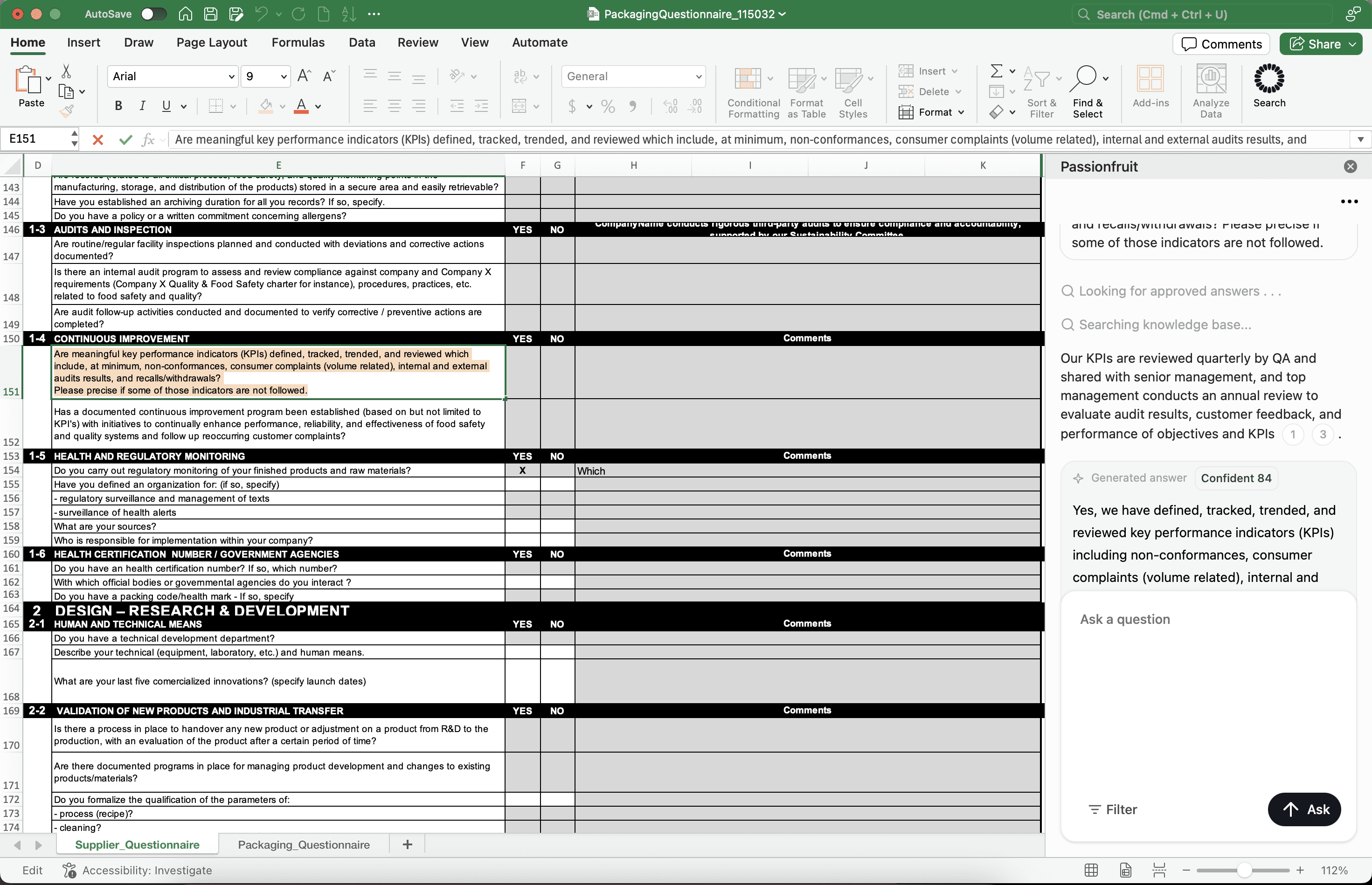

Making Supplier Approval Even Easier with Passionfruit Extensions

Collecting supplier data is only half the battle. The real challenge is making it easy for teams to handle that information without disrupting their daily routines. That’s why Passionfruit offers extensions in Microsoft add ons like Excel, Word, Powerpoint, Outlook, and more, bringing the approval process directly into the tools people already use.

For example, in Excel, questionnaires can be completed in the familiar spreadsheet environment, with responses flowing directly into Passionfruit. There’s no need to copy and paste between systems or worry about broken templates — the data arrives clean and ready to use.

By meeting people where they work, these extensions reduce friction and keep the supplier approval process moving forward. Compliance becomes less of a disruption and more of a natural part of everyday operations — which means faster responses, fewer delays, and less frustration on both sides.

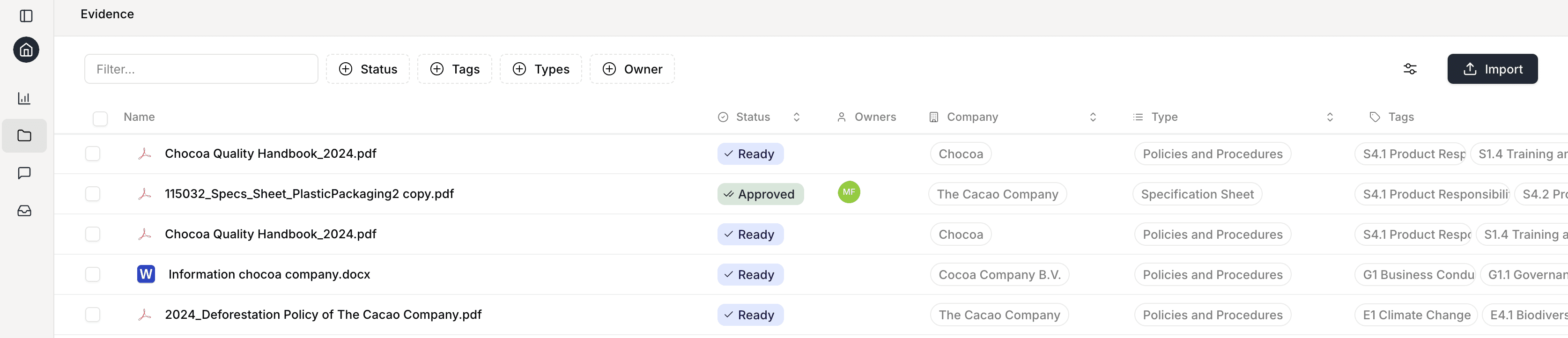

Building Confidence with Passionfruits Knowledge Hub

Supplier approval depends on information being accurate, accessible, and consistent. Too often, though, that knowledge ends up scattered across teams and systems — one department has the latest certificate, another holds the audit notes, and someone else keeps supplier contacts in a private spreadsheet. The result is gaps, delays, and plenty of back-and-forth whenever a questionnaire arrives.

Passionfruits knowledge hub brings all of this information together in one secure, central space. Every certificate, policy, and supplier record is stored where it can be found quickly, updated easily, and shared responsibly. When a questionnaire asks for proof, you don’t have to scramble — the answer is already there, ready to use.

This centralization not only saves time but also strengthens trust. Teams know they’re working from the same source of truth, and suppliers appreciate a smoother process that doesn’t involve repeating themselves. It’s a foundation that supports both compliance and collaboration — and it makes the domino effect of supplier approval far easier to manage.

Simplifying Responses with the Passionfruit Answer Library

One of the biggest frustrations with supplier approval is repetition. Different customers often ask the same questions in slightly different ways: Do you have a quality management system? Is your HACCP plan up to date? When was your last internal audit? Without a system, teams end up rewriting the same answers over and over, searching through past emails or copying from old questionnaires.

The Passionfruit Answer Library takes that repetition out of the process. Every time you answer a question, the response is stored, organized, and linked to supporting documents. The next time a similar question appears, you can reuse the approved answer instantly, with the option to adapt it if needed.

This doesn’t just save time — it ensures consistency. Auditors and customers see the same, reliable information across all questionnaires, while your team avoids the risk of errors that come with rushed or duplicated work. Instead of reinventing the wheel with every request, the Answer Library lets you build on what you’ve already done, turning past effort into future efficiency.

Conclusion: Keeping the Dominoes Standing

Supplier approval might look like another box to tick on a questionnaire, but it’s really about keeping your whole supply chain steady. Each partner you work with is a domino in the line — if one falls, everyone feels it. Strong approval processes help make sure they stand firm, from your direct suppliers to the ones behind them.

The hard part is managing it all without drowning in emails, chasing expired certificates, or copy-pasting the same answers over and over. That’s where Passionfruit steps in. With the knowledge hub, the answer library, and our extensions, supplier approval becomes less about paperwork and more about peace of mind.

Because when the dominoes stay standing, you’re not just compliant — you’re trusted. And that’s what really keeps business moving forward.